NEWS CENTER

GBXF made a brilliant appearance at the 2025 International Rubber and Plastics Exhibition Image

Release time:

2025-04-17

Exhibition area: 380,000㎡+

Over 4,500 international exhibitors

Over 3,800 mechanical exhibits

Over 1,600 raw material suppliers

Over 330,000 professional visitors

April 15th - 18th

CHINAPLAS 2025

It was grandly launched at the Shenzhen International Convention and Exhibition Center.

GBXF Booth Number: 13R2

Industry trendsetter

CHINAPLAS International Plastics and Rubber Exhibition was first held in 1983. As the world's leading exhibition in the plastics and rubber industry, this year's event is themed "Transformation, Collaboration, and Co-creating Sustainability", focusing on four key areas: "Circular Economy", "Digitalization", "Innovative Materials", and "High-End Technology Made in China". It strikes the main note of "Green + Intelligent" in the plastics and rubber industry. From the innovative achievements of advanced materials to intelligent manufacturing solutions, it highlights the latest breakthroughs and cutting-edge trends in the plastics and rubber industry.

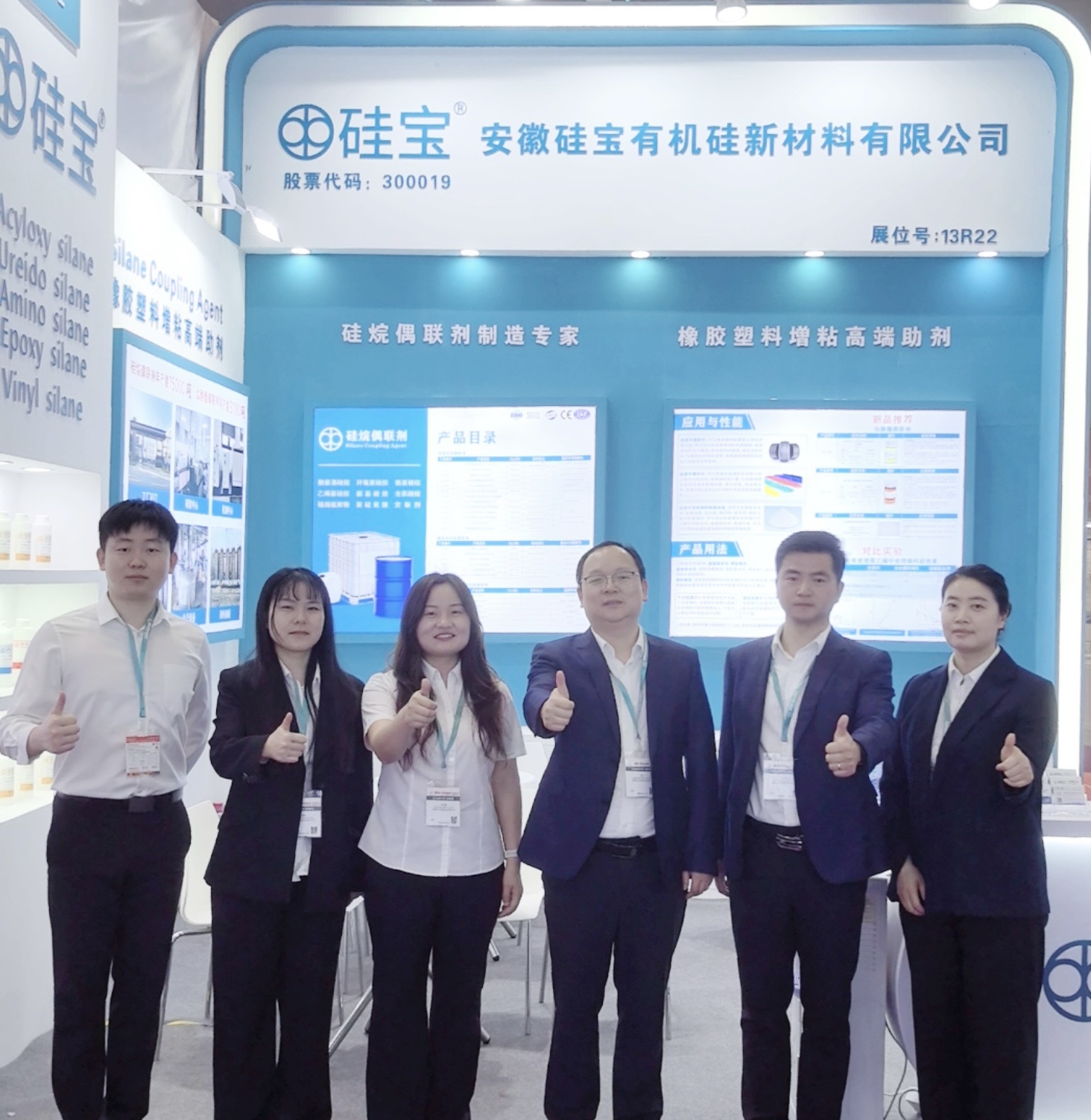

GBXF Exhibition Team

GBXF Exhibition Team

This time, GBXF showcased its series of silane coupling agents with great success, bringing high-performance solutions to the rubber and plastic industry and demonstrating the innovative power of silane modification to the world.

The booth of GBXF was constantly visited by customers.

The booth of GBXF was constantly visited by customers.

As a leading provider of high-quality solutions in the domestic rubber and plastic industry, GBXF has continuously invested in product innovation, launching a wide range of star products such as rubber coupling agents, silane coupling agents for engineering plastics and cables, including amino silanes, acyloxy silanes, vinyl silanes, polysiloxanes, and silane oligomers. These solutions have deeply empowered the new energy, intelligent automotive, electronics, 5G communication, aerospace and other fields, attracting many professional visitors to consult.

The Silibao team gave a detailed product presentation and technical exchange, and discussed issues such as low-carbon environmental protection and sustainable development with many domestic and foreign customers.

New Product Launch

Boost the localization process of silane.

The overseas team of GBXF answers customers' questions and provides solutions.

The overseas team of GBXF answers customers' questions and provides solutions.

With China having lifted visa restrictions for 38 countries, the number of overseas visitors has soared. As of now, more than 430 domestic and foreign buyer groups have confirmed their participation in the exhibition. GBXF has also received a large number of overseas clients, providing them with professional and enthusiastic services to address their concerns and lay the foundation for future cooperation.

In recent years, GBXF has successively appeared at international exhibitions, vigorously promoting its international market layout. With its outstanding technical capabilities, innovative product solutions and high-quality customer service, it has won project designations from many global application customers, and several of its products have already achieved batch shipments.

Exhibits on display in the form of pictures

Exhibits on display in the form of pictures

It is worth mentioning that Anhui Guibao has been continuously innovating in advanced production processes and green technology research and development. This time, it has launched an innovative solution and scientific and technological achievement - titanate coupling agent, which has a strong performance in terms of adhesion, mechanical properties and chemical properties when modifying resins such as PP, PE, PVC and ABS. GBXF has taken practical actions to promote the localization process of high-end silanes.

"Green + Smart"

Lead the main trend of the rubber and plastic industry

Green development is the backdrop of high-quality development; intelligence is making the rubber and plastic industry smarter.

After completing the expansion and renovation project last year, GBXF has integrated technologies such as automation, intelligence, and Internet of Things. Through process innovation, it has achieved a dual leap in production efficiency and product quality. While enhancing the efficiency of mechanical equipment, it also reduces the environmental impact of the process. GBXF is contributing to the sustainable growth of the industry with its strength and maintaining a competitive edge in the rapidly evolving intelligent environment.

Industry reports

Silicone Mall Interview

Silicone Mall Interview

Vice President Yang Qin stated in an interview with the media platform of the Organic Silicon Mall, "We are accelerating the localization process of silane through innovative technology and services."

As a national high-tech enterprise, GBXF, relying on the national enterprise technology center platform of its parent company, Guibao Technology, and building a "university-industry-research" collaborative innovation system, has established a provincial digital workshop and a municipal key laboratory for silicon-based new materials. It has also passed multiple authoritative certifications including ISO, REACH, RoHS, and SGS, and possesses nearly sixty independently developed patent technologies. It is accelerating the process of replacing imports.

Continuous in-depth development

Boost the high-quality development of the industry

Image GBXF

Plastic and rubber are penetrating all walks of life. The fields of new energy vehicles, high-end medical care, humanoid robots, eco-friendly packaging, and electronic appliances have a continuously growing demand for plastic technology, bringing new business opportunities to plastic raw materials and molding processes.

In the future, GBXF will continue to empower new quality productivity with technology and lead high-quality development with innovation, jointly promoting high-quality development in the rubber and plastic industry.

April 15-18

The exhibition continues to present exciting highlights

Shenzhen International Convention and Exhibition Center (Bao'an)

Booth No.: 13R22

Welcome all new and old friends to visit and guide

Explore the infinite possibilities of rubber and plastic intelligent manufacturing together!

Related News